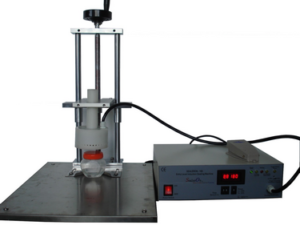

SealerOn™100

Following frequent inquiries for a reasonably priced induction machine from smaller businesses, some start-up companies, and testing laboratories, we have decided to make available a safe and affordable induction sealing unit. Smaller businesses have low budgets in mind, but it doesn’t mean that they are ready to compromise worker safety and product integrity. Regrettably, there are few good entry level induction machines in the market that offer security and peace of mind when it comes to the process associated with High Voltage, High Current and Strong Electromagnetic Frequency Radiation. Most low cost induction sealing units do not present CE safety certification. The SealerOn™ is constructed with the user safety and operation in mind. The equipment comes with European Compliance safety certifications for LV and EMF. Finally the Machinery is truly serviceable; Not a mess of wires that require soldering and a highly trained power electronics technician to change the main card.

SealerOn400™

The SealerOn™400 is supplied to seal Flat Cap Bottles and Jars with a closure size range of 1 in (28mm) to a little over 4 in (110mm). The typical conveyor speed range is 15 to 30 feet per minute (5 to 10 meters/min) depending on the cap size. A more dedicated tunnel sealing head is available for specialty caps. For larger diameter lids the sealing head is placed on a symmetric angle across the path of the product to achieve an even seal.

SealerOn3000™

The SealerOn™ 3000 is typically rated for Flat Caps of Diameter 20 mm to 120 mm traveling on a conveyor at speeds up to 20 Meters (60 Ft) per minute.

The Actual Speed needs to be determined with the Cap, Lining Material and Bottle combination to hand.

The Standard frame Allows the Sealing Head to be adjusted from 710 mm to 1200 mm above the floor Level. Technicians are not expected to repair any components.

Ideally a spare Generator is on hand or can be provided while the Generator is sent to our manufacturers service center for repair.

Our Capless Induction Machines

This is a real problem solving solution with a number of added advantages.

- Do you need to induction seal a product with a Metal Lid or a Metalized Lid?

- Do you need to induction seal a product with a Domed Lid?

- Do you need to induction seal a product where your cap can not be supplied with an induction seal?

- Do you need to induction seal a product that has no lid?

With our unique expertise and unique range of Capless Induction Sealing Equipment, we can solve your Capless induction sealing challenge of a small or large scale. We have a way to guide you and supply you with the cost effective induction sealing material to suit the process.

Heat Sealing for No Lid Products

Heat sealing is common for applications where the sealing diameter is more than 50mm. Production where size changeover is limited are well suited to heat sealing. The other main application for heat sealing will be where the product has no lid or cover and the sealing film is what is relied upon to complete the package.

Heat sealing is common for applications where the sealing diameter is more than 50mm. Production where size changeover is limited are well suited to heat sealing. The other main application for heat sealing will be where the product has no lid or cover and the sealing film is what is relied upon to complete the package.